Swan Manufacturing

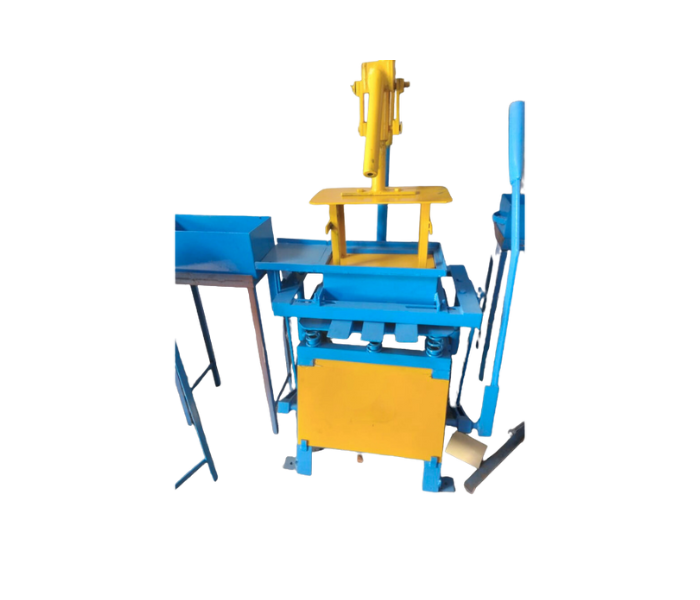

Fly Ash Brick Making Machine ( Fully Automatic | Semi-Automatic | Manual )

The Fly Ash Brick Making Machine range is designed to meet diverse production requirements—from small-scale startups to large industrial plants. Available in Manual, Semi-Automatic, and Fully Automatic configurations, these machines ensure highstrength, uniform bricks with efficient use of fly ash and other industrial by-products, supporting eco-friendly and costeffective construction.